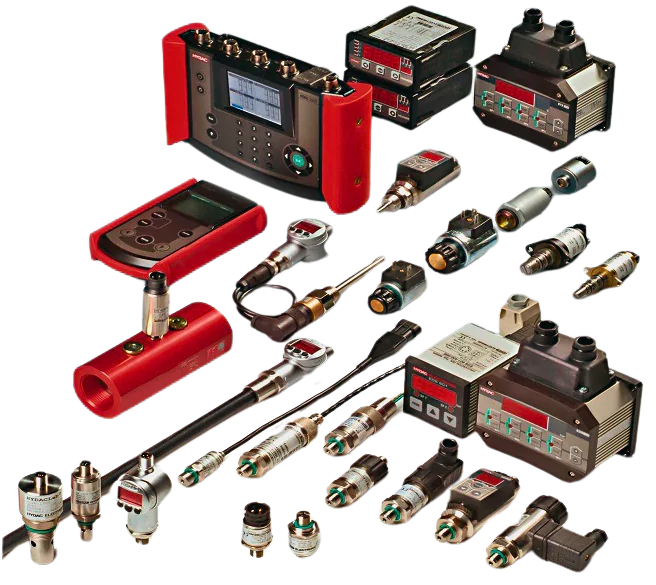

Electronic Sensors for Industrial Automation and Control

Modern industries are rapidly evolving, with machines and systems becoming increasingly digitized and automated. Electronic Sensors play a vital role in Industrial Automation and Control, as technology now drives every aspect of efficiency and precision.

Electronic sensors are at the heart of this transformation, providing accurate data for monitoring, diagnosis, and control.

Reliable sensors ensure safe operation, improved performance, and seamless integration across automation and mobile machinery systems.

Benefits of High-End Electronic Sensor Technology

A combined high-end electronic sensor technology approach delivers improved productivity, higher machine availability, longer operating life, and better business profitability.

Measurement & Monitoring Capabilities

We offer electronic sensors for precise measurement and online monitoring across critical parameters used in industrial automation and control systems:

- Pressure sensors

- Flow rate sensors

- Temperature sensors

- Speed sensors

- Fluid level sensors

- Linear position sensors

- Oil contamination sensors

- Condition monitoring sensors

Advanced Features & Interfaces

Our electronic sensors support a wide range of analog and digital interfaces (IO-Link, CAN, HART), and are available in variants for hazardous areas and safety-critical applications.

Choose from compact industrial proximity sensors, rugged pressure transducers, laser/optical particle counters, and multi-parameter condition monitoring units designed for automation systems.

Applications & Industry Fit

These sensors are suitable for automation, process control, mobile hydraulics, manufacturing, and infrastructure monitoring. Tell us your application and we’ll recommend sensor models, communication options, and mounting/integration accessories.

Find the Right Electronic Sensor Solution

Specify your requirements (measured variable, range, environment, interface) and our team will propose the ideal electronic sensors, switches, and integration plan tailored to your control system.

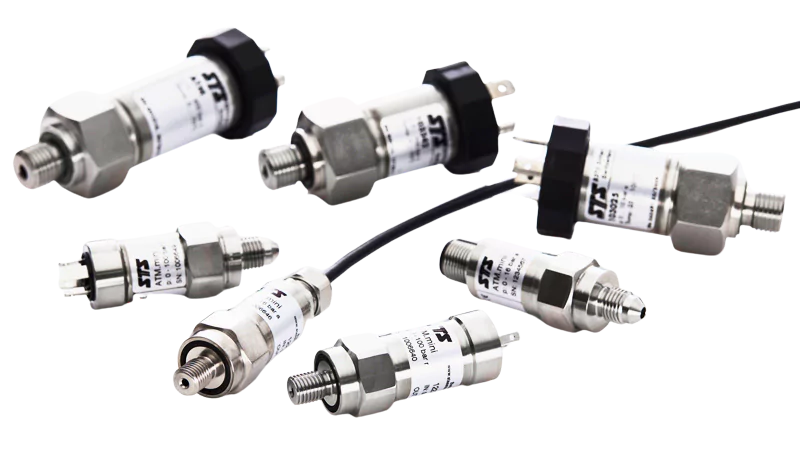

Pressure is one of the most critical physical variables in machines, systems, and installations. It not only needs to be measured and monitored but also precisely controlled to ensure reliable operation and, most importantly, safety. High-quality pressure sensors are vital to prevent malfunctions, enhance system performance, and protect operators from potential hazards.

Across industries including hydraulics, mobile machinery, oil & gas, power plants, machine tools, food & beverage, automotive, petrochemical, and refineries—pressure sensors ensure that critical pressure points are accurately measured, diagnosed, and controlled.

These advanced pressure transducers record pressure variables and convert them into electrical signals for monitoring and control. With a wide portfolio of transmitters ranging up to 1000 bar, we deliver high accuracy, robust designs, diverse output signals, and proven durability from leading global brands to match every industrial requirement.

Product Features

- Pressure range variants from 0 to 1000 bar.

- Thick-layer DMS on ceramic diaphragm for low-pressure ranges.

- Thin film DMS on stainless steel diaphragm for medium and high pressures.

- Over-pressure protection safeguards against bursts and surges.

- Excellent EMC characteristics ensure long-term signal stability.

- Accuracy class between 0.25% and 1.0% depending on version.

- ATEX, CSA, IEC Ex approvals available for explosion-proof environments.

Additional Benefits

- Certified by ABS, Lloyds, DNV, and BV for shipbuilding and offshore use.

- Customizable PSI and MPa adjustments.

- Rugged stainless-steel body ensures corrosion resistance and long service life.

Pressure measurement and control are critical in today’s automated and digitized operations, where systems need to be monitored and controlled both on-site and remotely.

An electronic pressure switch continuously monitors pressure levels and instantly opens or closes a switch contact once the pre-set pressure value is reached, ensuring reliable and safe operation across applications.

Designed for simplicity and reliability, these switches offer a wide measuring range, high switching cycles, and user-friendly operation. Available in versions with or without displays, they provide flexibility for diverse industrial applications.

Product Features

- Available in variants with or without measurement value display.

- Display options: fixed or rotatable on the longitudinal axis.

- Configurable with 1–4 switching contacts and 1 analog output (depending on version).

- LED display with 4-character readout for easy visibility.

- Compact, space-saving design for flexible installation.

- Factory-set or adjustable on-site via push buttons or foil keyboard.

- Variants available with IO-Link interface for advanced connectivity.

- IP67 protection rating for harsh environments.

- Approvals from ABS, Lloyds, DNV, and BV for marine and offshore use.

- Menu navigation compliant with VDMA standards.

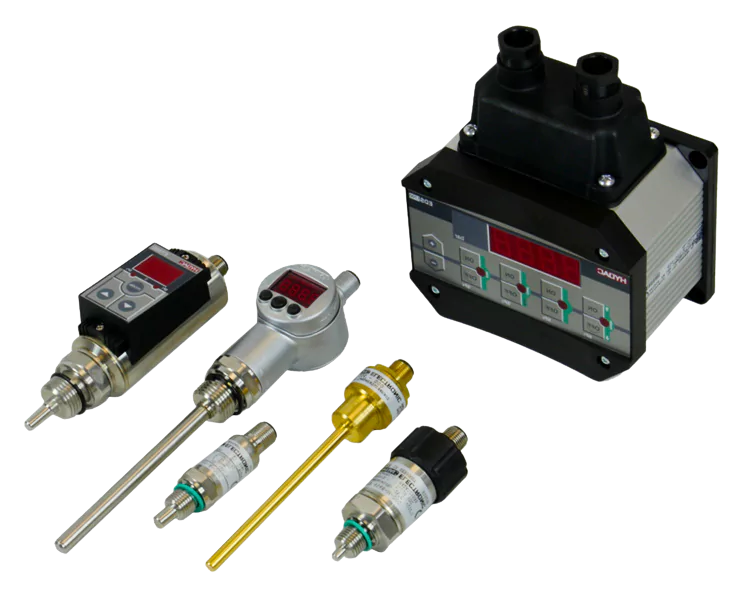

Temperature is one of the most critical physical parameters monitored in machines and installations. It must be measured and maintained within set limits to ensure safe, reliable, and efficient operation of any system.

In machine tool and automotive applications, temperature measurement of key components such as gears, motors, and drives provides vital insights into the machine’s condition. In steel and metal industries, monitoring cooling circuits is essential to prevent overheating and protect plant equipment.

Temperature transmitters and sensors record temperature and convert it into a proportional output signal. Electronic temperature switches, on the other hand, measure and process temperature values and provide a switching signal based on preset values.

Temperature Sensor / Transmitter Features

- Robust and compact design for industrial use

- Measuring range: -30°C to +150°C

- Signal output: 0…10 V or 4…20 mA

- Enclosure rating: IP65 / IP67

- Multiple process connection options with mechanical adapters

- High resistance to shock and vibration

Temperature Switch Features

- Measuring range: -30°C to +150°C

- Configurable with 1, 2, or 4 switch contacts

- Analog output: 0–10 V or 4–20 mA

- High measurement accuracy

- Local display (rotatable depending on model)

- Pressure-resistant design for pipeline installation

- Special versions available for tank installations

- User-friendly menu navigation

- Enhanced EMI protection

- Enclosure rating: IP65 / IP67

- Optional IO-Link communication for smart integration

Flow measurement requires dynamic, accurate, and reliable monitoring of flow and volume. To meet this need, we offer a range of flowmeters – Turbine type, Gear type, and Float type – designed for diverse applications and suitable for different fluid viscosities.

Turbine flowmeters operate on the turbine principle, measuring the speed of an impeller and converting it into fluid flow data. Engineered for continuous, high-precision monitoring, these meters deliver consistent performance even under the most demanding industrial conditions. They are rugged, durable, and built to international standards.

Flowmeter Specifications and Application Coverage

- Handles fluid viscosity range: 1 ….. 600 cSt

- Pressure resistance: up to 400 bar

- Flow measurement capacity: up to 600 lpm

- Standard output signal: 4 ….. 20 mA

- Provision for additional sensor connection (pressure/temperature)

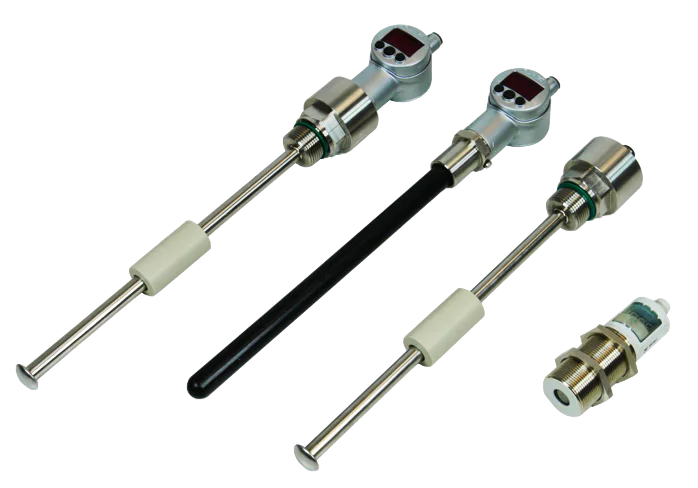

Electronic level sensors monitor operating fluid levels in hydraulic tanks, reservoirs, containers, and storage tanks. They are also crucial for detecting critical conditions, such as emptying of a reservoir or unintended tank over-spillage.

These sensors measure fluid levels and provide outputs in one or more switching signals (4 … 20 mA or 0 … 10V), according to pre-set values. Optional configurations include built-in temperature measurement and analogue output for advanced applications.

These electronic level sensors operate without mechanical parts or floats, making them highly reliable and robust in construction. Added advantages include local level indication and easy switch-point adjustment via soft buttons for simplified operation.

Product Features

- Capacitance-based proximity sensing technology

- 4-digit display with high signal resolution

- Available measuring probe lengths: 250 / 410 / 620 / 730 / 1000 mm

- 1, 2, or 4 independent PNP transistor switching outputs

- Analogue output: 0-10V or 4-20 mA

- Adjustable switching and switch-back points

- 320° rotatable display & electrical connection

- User-friendly operation with simple menu navigation

Portable Data Recorders & Hydraulic Testers

State-of-the-art portable instruments for diagnosing pressure, temperature, flow, speed, oil cleanliness, condition monitoring and hydraulic power in hydraulic and pneumatic systems.

These plug-and-measure devices accept sensors directly — connect the sensor, power up, and read measurements instantly via the built-in user interface.

Portable recorders can log multiple parameters simultaneously (or the same parameter at several measurement points). Data can be stored, exported and analysed on a PC or laptop — ideal for troubleshooting, commissioning and routine maintenance.

Typical Applications

- System commissioning and functional verification

- On-site troubleshooting and fault finding

- Condition-based maintenance and predictive analysis

- Performance validation after repairs or retrofits

User Benefits

- Increase plant and component availability through targeted actions

- Reduce unexpected downtime with early detection

- Lower operating and maintenance costs via preventive strategies

- Capture reliable, repeatable data for long-term trend analysis

Apart from the mentioned electronic sensors, we also provide a wide range of accessories to power, mount, and support their serviceability.

Optimum accessories for every sensor!

Available in multiple variants, these accessories ensure seamless installation, reliable operation, and time-saving during commissioning across all applications.

Electrical accessories include: Electrical connection male binder plugs with multiple pole options.

Mechanical accessories for sensor mounting/clamping include:

- Connection accessories for sensors with different thread profiles

- Clamps for wall mounting – screw type and weld type fittings

- Snubbers for pressure surge protection

- Vibration mounts for stable performance

- Protection sleeves for safe tank mounting

FAQ

Techknow Engineering Enterprise supplies advanced electronic sensors for measuring pressure, flow rate, temperature, speed, fluid level, oil contamination, and more, ensuring precise monitoring and control.

They provide accurate real-time data collection, diagnostics, and monitoring, enabling safer, more efficient, and fully automated industrial operations.

Benefits include improved productivity, higher machine availability, extended operating life, reduced downtime, and enhanced overall business profitability.

Our sensors are widely used in industrial hydraulics, mobile machinery, rail, road, air, underground, and underwater applications for reliable monitoring and automation.

We provide sensors with analog and digital interfaces, including IO-Link, CAN, and HART, allowing seamless system integration into modern industrial setups.

Yes, we supply sensors designed for explosive atmospheres and applications requiring enhanced functional safety, ensuring compliance with global safety regulations.

Absolutely. Our sensors are engineered for accurate and reliable measurement of both liquid and gaseous media across a wide range of industrial applications.

Simply share your application requirements with our experts, and we’ll recommend the most suitable sensor or switch tailored to your operational needs.

We provide high-quality Electronic Sensors from trusted manufacturers including Hydac, WIKA, and Keller, ensuring accurate monitoring, reliable performance, and long service life for hydraulic and industrial applications.