Hydraulic Pumps for Industrial and Mobile Applications

Hydraulic pumps are the driving force behind every hydraulic system, powering industrial machinery and mobile applications with unmatched precision and energy efficiency. The right pump selection ensures consistent pressure, reliable operation, and extended component life—reducing downtime and maximizing productivity across all fluid power systems.

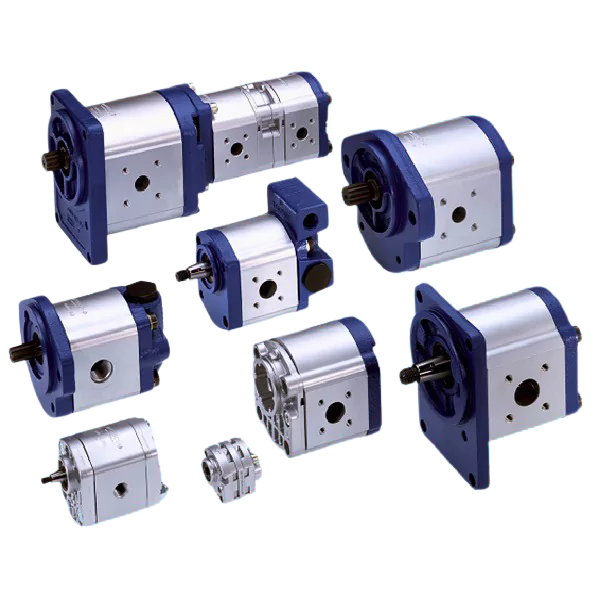

Wide Range of Oil Hydraulic Pumps

At Techknow Engineering Enterprise, we offer a comprehensive range of oil hydraulic pumps designed for diverse industrial and mobile applications. From piston and vane to gear pumps, our solutions are engineered for high performance and durability under demanding conditions.

Request a Quote

High Efficiency & Reliability

Built to deliver high working pressures, consistent reliability, and superior efficiency, our pumps help reduce operating costs while enhancing equipment productivity. These advantages make them ideal for construction, manufacturing, automotive, and heavy-duty industries.

Explore our full range of hydraulic accessories to complete your system setup.

Our line-up includes Axial Piston Pumps, Vane Pumps, Radial Piston Pumps, External Gear Pumps, Internal Gear Pumps, and Gerotor Pumps, covering a broad spectrum of industrial and mobile applications.

We provide hydraulic pumps and motors with multiple designs and setting ranges, delivering flows from 0.12 cm³/rev to 560 cm³/rev and working pressures up to 400 bar (standard) and 700 bar depending on the selected pump type.

Types & Classification of Hydraulic Pumps

Understanding the types of hydraulic pumps and their classification is essential for selecting the right solution for your equipment. Whether you require piston hydraulic pumps, vane pumps, or gear pumps, our team can help identify the best fit for your system requirements.

Reliable Hydraulic Pump Solutions for Every Application

At Techknow Engineering Enterprise, we help you source new hydraulic pumps or provide suitable alternatives if your existing model has become obsolete. Rexroth hydraulic pumps are among our most trusted solutions, known for their precision, efficiency, and durability across a wide range of mobile and industrial uses.

The importance of hydraulic pumps lies in their ability to convert mechanical energy into hydraulic energy, driving your system with reliable pressure and flow. By ensuring smooth operation and minimizing downtime, the right pump directly enhances productivity, efficiency, and equipment longevity.

Why Choose Our Hydraulic Pumps?

- Wide range: piston, vane, gear, radial piston, and gerotor pumps

- High operating pressure up to 700 bar

- Compact, efficient, and durable construction

- Trusted brands like Rexroth for superior performance

- Expert guidance in selecting the right pump for your system

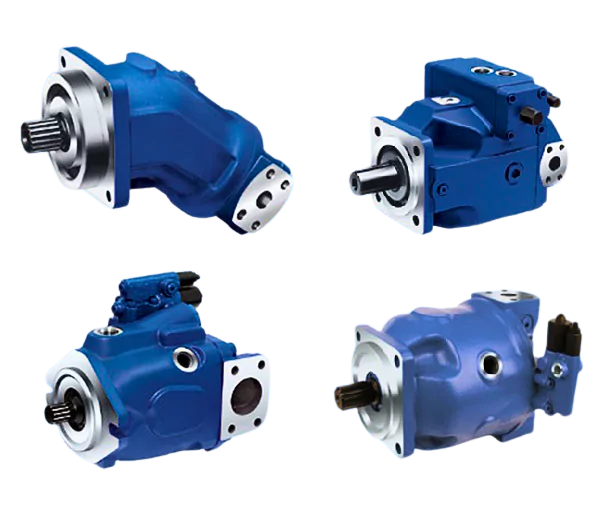

Axial Piston Pumps

Axial piston pumps are positive-displacement hydraulic pumps, available in both fixed displacement and variable displacement designs. In fixed displacement pumps, the output remains constant during each cycle, while variable displacement pumps allow adjustment of the displacement chamber geometry to change the flow rate and pressure as required.

With swash-plate and bent axis designs, these pumps are ideal for medium to heavy-duty applications in industrial machinery, mobile equipment, and construction systems.

These advanced hydraulic pumps feature un-load, variable pressure, load-sensing, and pressure-constant controls. Such control accessories allow operators to regulate fluid discharge per revolution and adapt system pressure based on load requirements. This results in optimized performance, power savings, and extended equipment life.

Available Configurations & Specifications

- Axial Piston Fixed Displacement Pump: Up to 400 bar, flow range 27 – 950 lpm (depending on version).

- Axial Piston Variable Displacement Pump: Up to 500 bar, flow range 32 – 1000 lpm (depending on version).

Fixed displacement pumps are best suited for open circuits, while variable displacement pumps, with flow control through swivel angle adjustment, can be used in both open and closed circuits for enhanced versatility.

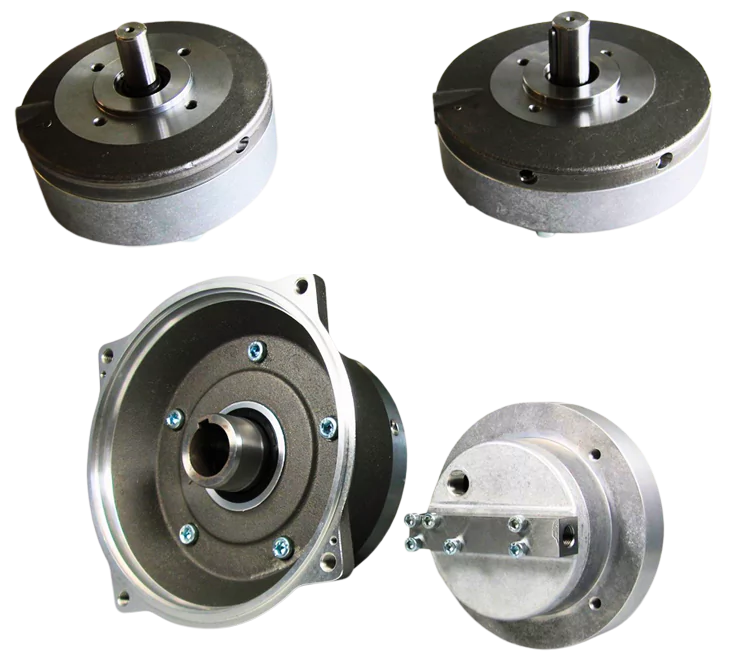

Radial Piston Pumps

Radial piston pumps are widely used in applications that demand high-pressure performance with relatively small flow ranges. These are fixed displacement, valve-controlled hydraulic pumps capable of delivering pressures up to 700 bar and, in some configurations, even 1000 bar. Their robust construction and high efficiency make them ideal for demanding industrial, mobile, and hydraulic system applications.

Key Features (depending on version series)

- Operating pressure: up to 700 bar (1000 bar possible in special variants)

- Displacement: 0.12 to 8.14 cm³/rev

- Speed range: 500 rpm to 3600 rpm

Product Advantages

- High volumetric and mechanical efficiency

- Accurate and fine delivery flow rate gradation

- Extended service life and durability

- Operation independent of the direction of rotation

Radial piston hydraulic pumps are particularly suitable for applications that require precise flow control, high reliability, and compact size. They are commonly used in machine tools, presses, test benches, and heavy-duty hydraulic machinery.

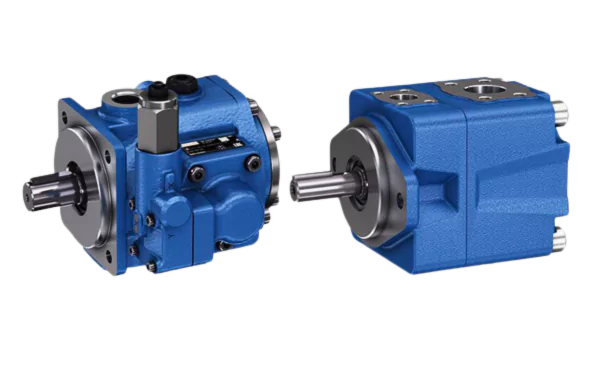

Hydraulic Vane Pumps

Hydraulic vane pumps generate pressure by channeling hydraulic fluid through a set of sliding vanes driven by an off-center shaft. As the shaft rotates, the vanes press against the pump wall, reducing chamber volume and increasing fluid pressure. This pressurized fluid is then directed through the system, delivering consistent flow for efficient hydraulic power transmission.

Vane pumps are available in fixed displacement and variable displacement designs, making them suitable for low to medium pressure hydraulic applications. They are widely used in industrial machinery, mobile equipment, and automotive systems.

Available Variants

- Fixed Displacement Vane Pumps: Up to 210 bar, flow rate 5 – 285 lpm (version-specific)

- Variable Displacement Vane Pumps: Up to 160 bar, flow rate 37 – 270 lpm (version-specific)

Features & Advantages

- Uniform discharge with negligible pulsations

- Low operating noise for quieter system performance

- Extended service life with hydro-dynamically lubricated plain bearings

- Capability to control pressure and flow as per system requirements

- Standardized mounting and connection dimensions for easy integration

- Can be combined with axial piston pumps, gear pumps, and radial piston pumps for system flexibility

Whether you need a compact, quiet, and efficient pump for your hydraulic system, or are exploring different types of hydraulic pumps, vane pumps provide a balance of efficiency and reliability, making them a preferred choice in many industries.

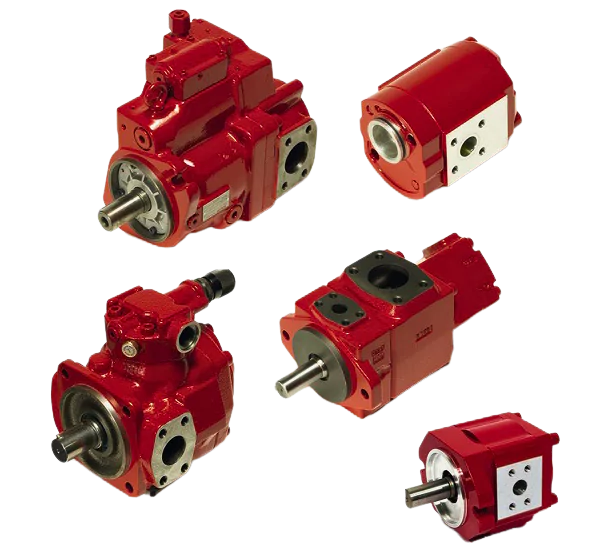

Hydraulic Gear Pumps

Gear pumps are among the most widely used hydraulic pumps due to their simple design, cost-effectiveness, and reliable performance. They operate by the meshing of two gears that force hydraulic fluid around the gears, creating smooth and consistent flow.

Gear pumps are available in two types: External Gear Pumps (using two meshing spur gears) and Internal Gear Pumps (featuring one external and one internal spur gear with inward-facing teeth).

At Techknow Engineering Enterprise, we supply a wide range of high-powered gear pumps manufactured as per international standards, catering to industrial, commercial, and mobile hydraulic applications.

Gear Pump Options

We offer gear pumps as single units and multiple units with various flange mounting configurations to match your system needs.

- External Gear Pumps: Up to 280 bar, displacement 0.25 – 100 cc/rev

- Internal Gear Pumps: Up to 350 bar, displacement 1.70 – 250 cc/rev

- Special Gear Pumps: Designed for high-viscosity oil (above 220 CST)

Key Features of Hydraulic Gear Pumps

- High mechanical and volumetric efficiency

- Low noise operation for smoother performance

- Compact and lightweight design with excellent power-to-weight ratio

- Available in multiple shaft, flange, and port variations

- Durable construction ensuring long service life

Whether you require external gear pumps for mobile machinery or internal gear pumps for industrial systems, our wide range ensures reliable performance across different applications. Understanding the classification of hydraulic pumps is essential for selecting the right solution, and our experts can help guide your choice.

Gerotor Hydraulic Pumps

Gerotor pumps are a type of positive displacement pump that use an inner and outer rotor. The unique geometry of the rotors partitions the volume into chambers, which enables smooth and efficient fluid transfer. These pumps are widely used in oil hydraulic systems due to their compact size, low noise, and energy efficiency.

Key Features of Gerotor Pumps

- Maximum operating pressure: 15 bar

- Flow rate range: 10 to 150 lpm

- Very low operating noise – ideal for sensitive applications

- Compact, lightweight design with high efficiency

- Low energy consumption for cost savings

- Excellent suction behavior for smooth operation

- Can be combined with axial piston, vane, and internal gear pumps

With their unique rotor design and efficiency, Gerotor hydraulic pumps are suitable for applications requiring smooth, quiet, and compact hydraulic solutions. They are commonly used in automotive, mobile machinery, and industrial equipment.

FAQ

Hydraulic pumps are the heart of hydraulic systems, converting mechanical energy into hydraulic energy to efficiently power industrial and mobile machinery.

Hydraulic pumps ensure smooth operations, reduce downtime, boost productivity, and deliver the pressure and flow required for various hydraulic systems in both industrial and mobile equipment.

We offer a broad range of pumps to suit different needs, including:

- Axial Piston Pumps

- Radial Piston Pumps

- Vane Pumps

- External Gear Pumps

- Gerotor Pumps

Our pumps cover flows from 0.12 cm³/rev to 560 cm³/rev with pressures typically up to 400 bar, and in some cases reaching as high as 700 bar, depending on the pump type.

Our experts help you choose the right pump based on your application, required flow rate, pressure needs, and machinery type to ensure maximum efficiency and performance.

Yes. We specialize in sourcing equivalent models from trusted manufacturers, ensuring your systems continue to run reliably and efficiently without disruptions.

Rexroth pumps are known for precision, durability, and energy efficiency, ensuring consistent performance while optimizing power delivery in industrial and mobile machinery.

- High efficiency and reliability

- Wide flow and pressure ranges for diverse applications

- Advanced technology for longer service life

- Compatibility with industrial and mobile hydraulic systems

We provide high-quality hydraulic pumps from trusted manufacturers including Hydac, Rexroth, Yuken, Eaton-Vickers, Parker, Dowty, Polyhydron, and Beiri Hawe, ensuring reliable performance, long service life, and compatibility with a wide range of industrial applications.