Introduction to Hydraulic Valves

Hydraulic valves are essential for controlling oil flow and pressure within hydraulic systems. Each valve uses a precisely machined spool inside a durable cast-iron or steel body to direct fluid between pumps, actuators, and tanks. Depending on the design, these valves can be mechanically, electrically, or hydraulically actuated, offering precise flow control and reliable operation across industrial and mobile applications.

Request a Quote

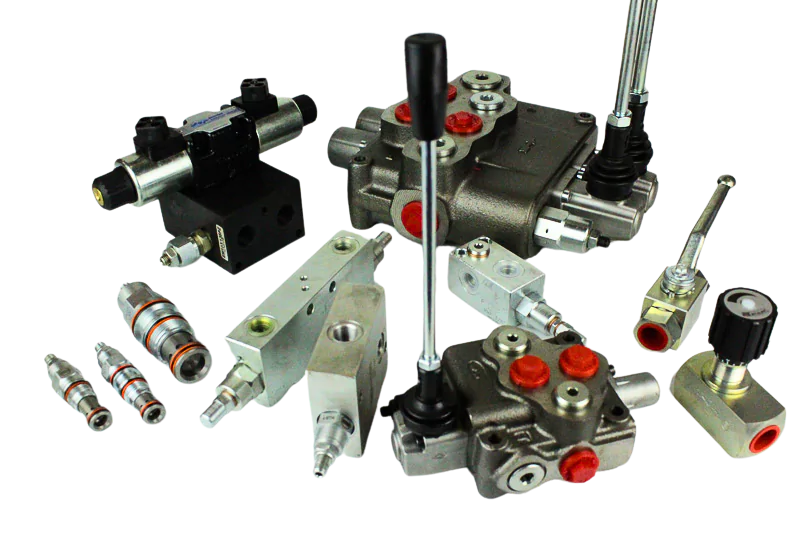

Wide Range of Hydraulic Valves, Repair Kits & Accessories

Techknow Engineering Enterprise supplies a comprehensive range of hydraulic valves, valve repair kits, and hydraulic accessories for industrial and mobile applications. Each component is engineered for durability, precision, and cost-effective performance, ensuring long-term reliability and optimal fluid control in every hydraulic system.

Innovative Hydraulic Valve Solutions

Our hydraulic valve solutions are designed to enhance equipment productivity, reduce maintenance downtime, and maximize operational efficiency. Whether you need proportional, directional, or pressure-control valves, we deliver high-performance solutions that meet global industrial standards.

Our Hydraulic Valves Program Includes

- Directional control hydraulic valves

- Pressure control hydraulic valves

- Flow control hydraulic valves

- Check valves

- Logic valves

- Cartridge valves

- Mobile control valves

- Hydraulic valve accessories & seal kits

We supply a wide range of hydraulic valves from leading brands such as Rexroth, Parker, and Bucher, along with reliable alternatives. Whether you need different types of hydraulic valves for industrial, mobile, or custom applications, our team can help you select the best solution.

Directional Control Hydraulic Valves

Directional control hydraulic valves are essential for regulating the flow of hydraulic fluid within circuits—allowing operators to start, stop, and change the direction of flow with precision.

Our valves, sourced from trusted principals and associates, include direct-acting and pilot-operated two-way poppet valves, as well as direct-acting spool valves. They are designed as per international mounting standards and provide 3-way or 4-way directional control. With flexible actuation methods such as solenoid, hydraulic pilot, lever, or mechanical operation, these valves are ideal for a wide range of industrial and mobile applications.

Our Product Line Includes

- On/Off Directional Valves

- Proportional Directional Valves

- Servo Directional Valves

Key Specifications (Depending on Type)

- Max. operating pressure: up to 700 bar

- Max. flow rate: up to 1100 lpm

- Nominal valve sizes: NG06 to NG32

- Mounting options: Sandwich & Sub-plate

- Multiple spool position configurations

- Actuation methods: Hydraulic, Pneumatic, Hand lever, or Solenoid

- Standard supply voltage: 12V, 24V, 110V, 230V (custom options available)

Trust our directional control hydraulic valves to optimize your hydraulic systems, reduce downtime, and enhance productivity. With superior performance and proven reliability, we deliver the right solution for your industrial or mobile application needs.

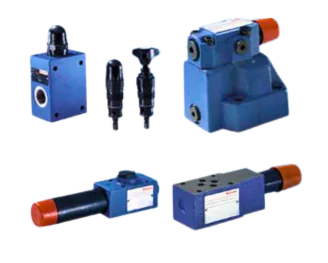

Pressure Control Hydraulic Valves

Pressure control valves are essential safety components in hydraulic systems, designed to regulate and control pressure levels to manage actuator force effectively. Our valves, sourced from trusted principals and associates, meet stringent industry standards to deliver maximum reliability, precision, and performance.

Product Range

- Pressure Relief Valves

- Proportional Pressure Relief Valves

- Pressure Reducing Valves

- Proportional Pressure Reducing Valves

- Pressure Sequence Valves

- Pressure Cut-Off Valves

Key Specifications (Depending on Type)

- Maximum operating pressure: up to 500 bar

- Maximum flow rate: up to 650 lpm

- Nominal valve sizes: NG06 to NG30

- Mounting types: Threaded, Screw-in Cartridge, Sandwich & Sub-plate

- Multiple spool position configurations

- Actuation methods: Manual, Mechanical, Solenoid, or Electronic

Maximize safety, reliability, and system efficiency with our precision-engineered pressure control hydraulic valves. Designed to handle demanding applications, they help protect critical components while ensuring smooth hydraulic operations.

Hydraulic Flow Control Valves

To ensure precise control functions in hydraulic systems, regulating oil flow is essential. Our wide range of hydraulic flow control valves are designed to deliver accuracy, reliability, and durability for industrial and mobile applications.

These valves are user-friendly, featuring a slotted control spindle for easy operation. Adjusting the spindle via a control knob allows operators to vary the flow rate by changing the cross-section at the throttle point, ensuring optimal performance in every application.

Product Variants Available

- Inline mounting flow control valves

- Manifold mounting options

- Sandwich plate design

- Cartridge mounting valves

- Pressure compensated types

- With or without check valve feature

Technical Specifications

- Maximum operating pressure: 350 bar

- Maximum flow rate: 400 lpm

- Nominal valve sizes: 06 to 30

- Standard cracking pressure: 0.5 bar

- Seals available in Perbunan (NBR) or Viton (FKM)

Our flow control valves ensure safe, smooth, and efficient hydraulic operations. Designed for precision, these valves are compatible with leading brands such as Rexroth, Parker, and Bucher, making them a versatile choice for diverse industries.

Contact Techknow Engineering Enterprise today to explore our complete range of hydraulic flow control valves and find the perfect solution for your system requirements.

Hydraulic Check Valves

Hydraulic check valves are critical components in hydraulic systems, ensuring that fluid flows in only one direction while preventing backflow. Featuring a simple yet reliable design, these valves typically use a ball mechanism that opens and closes automatically based on fluid pressure.

By preventing reverse flow, check valves protect system integrity, reduce the risk of component damage, and maintain operational efficiency. They are widely used in applications where maintaining system pressure or avoiding fluid contamination is essential.

Available Configurations

We offer a comprehensive range of hydraulic check valves to meet diverse industrial requirements. Options include:

- Inline mounting check valves

- Sandwich plate design

- Cartridge mounting options

- Manifold mounting designs

Technical Specifications

- Maximum operating pressure: 350 bar

- Maximum flow rate: 450 lpm

- Nominal valve sizes: 06 to 32

- Standard cracking pressure: 0.5 bar

- Seals available in Perbunan (NBR) or Viton (FKM)

Engineered for durability and high performance, our check valves are sourced from trusted principals and associates. Whether you need inline hydraulic check valves, cartridge check valves, or manifold-mounted options, we deliver solutions that ensure safe and efficient hydraulic operations.

Contact Techknow Engineering Enterprise today to find the right hydraulic check valve for your system and enhance the reliability of your hydraulic applications.

Hydraulic Logic Valves

Compact 2-port slip-in cartridge logic valves, sourced from our trusted principals and associates, are designed to control large volume flows in diverse industrial applications. When paired with compatible control covers, they offer versatile configurations to suit various hydraulic system needs.

Logic valves enable precise regulation of pressure, flow, and flow direction within hydraulic circuits. Their robust construction allows them to manage high nominal flow rates while maintaining minimal pressure drop. This provides significant advantages such as compact design, space efficiency, and reduced hydraulic block costs.

Product Range Specifications

- Maximum operating pressure: 420 bar

- Maximum flow rate: up to 25,000 lpm

- Nominal valve sizes: 16 to 160

Benefits of Hydraulic Logic Valves

- Accurate control of fluid dynamics in hydraulic circuits

- Durable design ensures long-lasting performance

- Minimal pressure drop for energy efficiency

- Cost-effective solution due to compact and modular design

Our comprehensive range of hydraulic logic valves is engineered to optimize flow control, improve system efficiency, and reduce operating costs across a wide variety of industrial applications.

Contact Techknow Engineering Enterprise today to explore our complete line of logic valves and discover how we can help you enhance your hydraulic system performance and operational efficiency.

Hydraulic Cartridge Valves

Experience unmatched hydraulic control solutions with our comprehensive range of hydraulic cartridge valves sourced from trusted principals and associates. Designed to tackle space constraints without compromising performance, our cartridge valves cover a wide variety of hydraulic applications across industries.

Types of Cartridge Valves Offered

- Pressure Relief Valves

- Pressure Reducing Valves

- Flow Control Valves

- Check Valves

- Counterbalance Valves

- Shuttle Valves

- Sequence Valves

- Solenoid Operated Poppet Cartridge Valves – 2/2 and 3/2 way

- Solenoid Operated Spool Cartridge Valves – 2/2, 3/2, 4/2, and 4/3

- Proportional Valves

- Manifold Block Valve Assemblies

Product Specifications

- Pressure rating: up to 420 bar (6000 psi)

- Flow rate: up to 600 lpm

- Nominal valve sizes: 06 – 25

- Available in UNF and metric cavities

- Manual override option available

Benefits of Hydraulic Cartridge Valves

- Compact design, ideal for systems with space constraints

- High durability and reliable operation

- Wide variety of configurations for versatile use

- Enhanced safety and performance in hydraulic circuits

- Optimized for industrial and mobile hydraulic systems

Our cartridge valves are engineered to deliver optimum performance, ensuring reliable operation and safety. Whether you’re managing space-limited designs or high-performance hydraulic systems, our cartridge valves provide the perfect solution.

Contact Techknow Engineering Enterprise today to explore our complete range of hydraulic cartridge valves and discover how we can help optimize your hydraulic operations with premium quality solutions.

Mobile Control Valves

Explore efficiency and precision with our range of mobile control valves sourced from our trusted principals and associates. Designed with a compact yet robust structure, these valves incorporate inlet and outlet elements, along with directional valve components, following the advanced 6-way principle for optimal hydraulic control.

Engineered for reliability and high performance, our mobile hydraulic valves offer seamless control over hydraulic functions in mobile machinery and equipment. Their advanced design ensures smooth operation, minimal leakage, and maximum efficiency, making them ideal for construction, agricultural, and material-handling applications.

Key Features of Mobile Control Valves

- Maximum operating pressure: 350 bar

- Maximum flow rate: 70 lpm

- No. of spool axes: 1 to 10

- Sandwich plate design for flexibility

- Type of actuation: Hydraulic or Mechanical

- Circuit types available: Parallel, Tandem, or Series

- Compact design for space-saving installations

- Low internal leakage and reduced pressure losses

Why Choose Our Mobile Hydraulic Valves?

- Enhanced precision and reliability in demanding mobile applications

- Versatile configurations to suit diverse hydraulic systems

- Durable and long-lasting performance under heavy-duty conditions

- Designed to maximize efficiency and reduce downtime

Elevate the performance of your mobile hydraulic systems with our precision-engineered mobile control valves. Whether for mobile cranes, excavators, loaders, or other hydraulic-driven equipment, these valves ensure seamless functionality and superior productivity.

Contact Techknow Engineering Enterprise today to discuss your requirements and discover the right mobile control valve solution for your application.

Hydraulic Valve Accessories

Discover the essential hydraulic valve accessories designed to maximize performance, reliability, and efficiency in hydraulic systems. Our accessories are sourced from trusted principals and associates, ensuring compatibility and long-lasting durability in industrial and mobile applications.

Our Hydraulic Valves Program Includes

- Solenoid Coils: Available for NG 06 and NG 10 multi-brand control valves. Options include 12 VDC, 24 VDC, 110 VAC, and 230 VAC configurations. Standard DIN plug connections with multiple pin options for seamless integration.

- Sub-plates: Provide a sturdy mounting platform for valves, ensuring proper alignment and reliable support within hydraulic circuits.

- Electrical Connectors: Enable smooth integration of valves into electrical systems, ensuring efficient communication and control.

- Valve Amplifiers: Amplify electrical signals to regulate valve functions with high precision, enhancing responsiveness and accuracy.

- Cable Sets: Essential for connecting valves to power sources and control units, ensuring reliable power distribution and signal transmission.

- Seal Kits: Tailored kits with O-rings and seals designed for specific valves, protecting against leaks and maintaining consistent performance.

Explore our comprehensive range of hydraulic accessories tailored to meet your specific requirements. From solenoid coils to seal kits, we provide everything needed to enhance the efficiency, reliability, and safety of your hydraulic applications.

Contact Techknow Engineering Enterprise today to learn more about our hydraulic valve accessories and discover the right solution for your system requirements.

FAQ

Hydraulic valves regulate the flow and pressure of hydraulic oil within a system, ensuring safe, smooth, and controlled operation of machinery.

We supply a wide range of hydraulic valves, including:

- Direction Control Valves

- Pressure Control Valves

- Flow Control Valves

- Check Valves

- Logic Cartridge Valves

- Mobile Control Valves

- Accessories and Seal Kits for mobile control systems

We supply valves from trusted global manufacturers including Hydac, Rexroth, Yuken, Eaton-Vickers, Parker, Sun, Beiri, Hawe, Bucher, and Argo-Hytos, ensuring durability and long service life for diverse hydraulic applications.

Hydraulic valves function through mechanical or electrical activation of a spool inside a valve body, which regulates hydraulic oil flow and maintains system control.

Yes. We stock tools, repair kits, and spare parts, enabling cost-effective upgrades or replacements of existing hydraulic valves for improved system reliability.

Hydraulic valves support efficient fluid control across industries such as:

- Construction

- Manufacturing

- Mobile Equipment

- Marine Vessels

- Mining

- Industrial Automation

Yes. We develop innovative, tailored solutions to meet specific operational requirements, enhancing productivity and reducing downtime while minimizing operational risks.

Yes. In addition to hydraulic valves, we also supply high-quality ball valves and related accessories suitable for a wide range of industrial applications.

We provide high-quality hydraulic valves from trusted manufacturers including Hydac, Rexroth, Yuken, Eaton-Vickers, Parker, Sun, Beiri, Hawe, Bucher, and Argo-Hytos, ensuring durable performance, reliable operation, and long service life for industrial hydraulic systems.