Why Oil Filtration & Contamination Sensors Are Essential

Modern hydraulic systems operate with continuous movement, creating constant friction between components. Without proper oil filtration, this friction generates particles that contaminate hydraulic oil and affect performance.

The Impact of Oil Contamination

Studies reveal that nearly 80% of hydraulic system failures are caused by contaminated oil. Oil contamination sensors detect early changes in fluid cleanliness, helping prevent costly machine downtime, production losses, and component wear. Integrating real-time oil monitoring ensures longer equipment life and improved hydraulic efficiency.

Request a Quote

Proactive Contamination Control

By integrating oil filtration and contamination sensors, you can monitor cleanliness levels in real time, detect early warning signs, and extend the lifespan of hydraulic components. This proactive approach helps reduce breakdowns, improve efficiency, and lower maintenance costs.

This includes identifying and monitoring sources of contamination while installing an effective Oil Filtration & Contamination Sensors system tailored to the system's components and operations. By integrating advanced filtration technology with precise oil contamination measuring sensors, significant benefits can be achieved in terms of increased productivity, enhanced machine uptime, extended equipment lifespan, and improved business profitability.

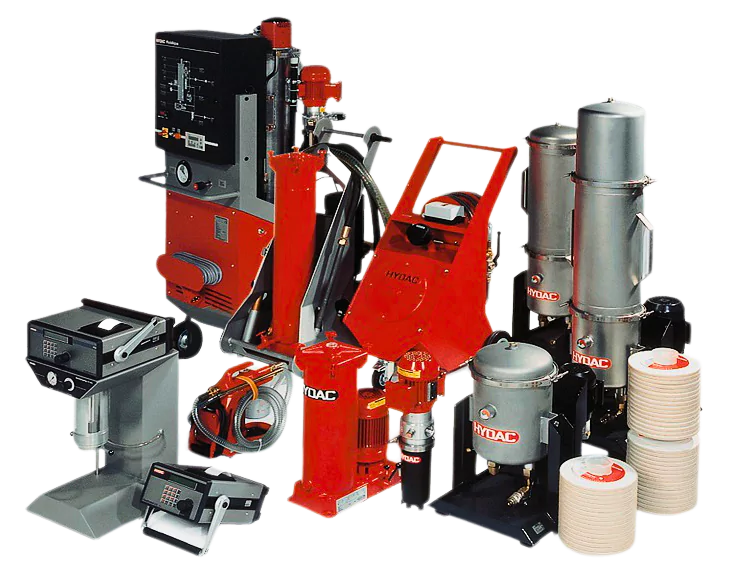

Oil Filtration & Contamination Sensors include

Types of Oil Filtration & Contamination Sensors

Oil Filtration Units

- Portable and mobile oil filtration units

- Electrostatic oil filtration units

- Low vacuum dehydration units

Oil Contamination Measuring Sensors

- In-line oil particle counters for ISO/NAS measurement

- Automatic laser particle counters

- Aqua sensors / water content sensors

Why Choose Our Oil Filtration & Contamination Sensors?

From offline filtration units for routine maintenance to continuous filtration systems for critical operations, our solutions are engineered to meet diverse requirements. With customizable options for filter media, flow rates, and filtration levels, our systems can be tailored to suit the specific needs of any application.

By maintaining the cleanliness of hydraulic fluids, our oil filtration & contamination sensors enhance the reliability and performance of hydraulic equipment. The result? Reduced wear, minimized downtime, optimized efficiency, and a significant extension of your system’s lifespan and productivity.

Take Action Today

Contact us today to explore our hydraulic oil filtration & contamination sensor solutions and discover how we can help you improve equipment reliability, reduce downtime, and boost operational efficiency.

Request a QuotePortable Hydraulic Oil Filtration Units

Our Portable Hydraulic Oil Filtration solution is designed to transform industrial maintenance by ensuring clean oil, reduced downtime, and extended equipment life.

Built for versatility and maneuverability, these units effectively remove contaminants, maintain oil quality, and improve system reliability. Perfect for transferring hydraulic oils and purifying hydraulic systems, they provide maximum operational efficiency.

Compact yet powerful, these mobile filtration units can be quickly deployed across facilities for routine maintenance, commissioning, or servicing—helping you keep operations running smoothly.

Product Specifications

- Operating pressure: 5 bar

- Flow rate: 10 to 15 lpm

- Pump type: Gear Pump

- Viscosity range: up to 100 cst (standard)

- Filter rating: 1 to 60 µm

- Filter materials: In-organic fibre, Wire mesh

- Weight: 18 kgs

Key Features

- Lightweight and Portable – can be hand lifted

- Compact and space-saving design

- Easy maintenance with Spin-On cartridges

- Fast element replacement with minimal downtime

- Durable build for long service life

- Simple handling for industrial teams

Mobile Oil Filtration Units for Hydraulic Systems

For machinery reliant on oil lubrication, a mobile oil filtration unit is indispensable in ensuring long-term performance and durability.

Our Mobile Filtration Units are engineered to handle diverse hydraulic servicing needs. They excel in circulating and delivering clean, filtered hydraulic and lubrication oils, preserving system integrity and reliability.

These units operate via mechanical off-line filtration, where hydraulic oil is pumped through high-performance filters to capture particles of all sizes. This process ensures lubricant cleanliness, minimizes contamination, and extends equipment life.

Key Features of Mobile Filtration Units

- Facilitates oil flushing during commissioning

- Achieves exceptional oil cleanliness ratings

- Optional integration with oil cleanliness sensors

- Extends equipment lifespan and reduces downtime

- Compact, easy handling for on-site use

- Compatible with all conventional operating media

Product Specifications

- Operating pressure: up to 10 bar

- Flow rate: 20 lpm to 100 lpm

- Pump type: Gear Pump

- Viscosity range: up to 100 cst (standard)

- Filter rating: 3 to 100 µm

- Multi-stage filtration: 1, 2 & 3 stages available

- Filter materials: In-organic fibre, Wire mesh, Paper, Water-absorbent

- Filtration type: Absolute or nominal (depending on filter media)

- Weight: 75 to 200 kgs

Why Choose Our Mobile Filtration Systems?

Engineered for comprehensive hydraulic maintenance, our Mobile Oil Filtration Units deliver clean oil, optimize system performance, and minimize downtime. They provide a cost-effective solution that ensures long-term reliability and equipment protection.

Contact us today to explore customized solutions for your application and discover how our mobile filtration systems can help you achieve substantial cost savings and improved uptime.

Electrostatic Oil Filtration Unit for Hydraulic Systems

Experience superior oil cleanliness and equipment protection with our Electrostatic Oil Filtration Unit. Specially engineered to remove submicron-level contaminants, it ensures longer oil life, reduced downtime, and extended service life of critical hydraulic components.

How Electrostatic Oil Filtration Works

Operating on the principle of electrostatic separation, the unit applies high voltage (6 KV / 12 KV) to attract charged particles toward electrodes. These impurities are captured and removed continuously, achieving NAS 1638 cleanliness class 6–7 without disrupting system operations.

Key Features & Specifications

- Removes contaminants at submicron levels

- Captures particles regardless of shape, size, or material

- Nominal oil flow rate: 2 to 10 lpm

- Power consumption: 250 W – 550 W

- Low-cost spare filter paper consumables

- Designed for continuous online filtration

Benefits of Using Electrostatic Oil Filtration Units

Continuous use of our Electrostatic Oil Filtration Unit, tailored to your hydraulic oil tank volume, provides:

- Cleaner oil and longer equipment lifespan

- Improved system efficiency and reliability

- Reduced operating and maintenance costs

- Support for environmental sustainability by extending oil usage

Low Vacuum Dehydration Unit for Oil & Hydraulic Fluids

The presence of water in oil accelerates acidification, causes corrosion, reduces load capacity, and hastens oxidation—leading to costly failures and downtime.

Our Low Vacuum Dehydration Unit, sourced from leading principals and associates, provides a cost-effective solution for oil dehydration in lubrication and hydraulic systems. Designed for off-line filtration, it ensures dependable oil maintenance across a wide range of industrial applications.

How It Works

Using the principle of vacuum dewatering, the unit heats oil gently (45°C–55°C) inside a vacuum chamber. This process effectively separates free & dissolved water as well as dissolved gases from hydraulic and lubrication fluids—preserving oil integrity and extending system lifespan.

Key Features of Low Vacuum Dehydration Unit

- Removes free & dissolved water, plus dissolved gases

- High contamination retention (up to 2.5 kg depending on element)

- Operating pressure range: 0 – 6 kg/cm²

- Nominal oil flow rate: 6 – 20 lpm

- Eco-friendly process, no chemicals required

Benefits of Using a Low Vacuum Dehydration System

- Preserves oil quality and integrity

- Minimizes equipment downtime

- Reduces maintenance and replacement costs

- Extends service life of hydraulic & lubrication systems

- Improves overall system efficiency and reliability

With our Low Vacuum Dehydration Unit, you can achieve cleaner oil, seamless operations, and significant long-term cost savings.

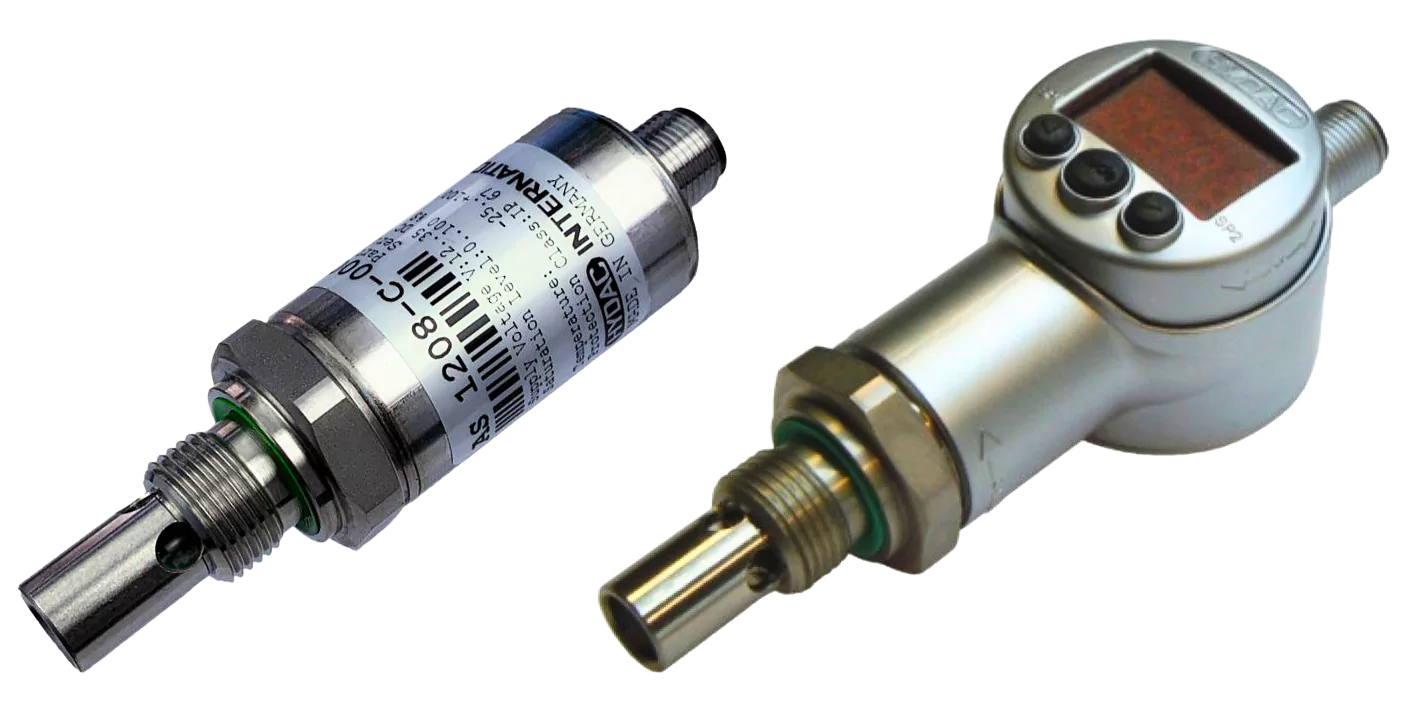

The Oil Contamination Monitor stands as a vital tool for maintaining optimal performance and longevity in hydraulic and lubrication systems. Its primary function is to measure and analyze oil contamination levels, providing crucial insights into the cleanliness of the fluid.

The Oil Contamination Monitor employs advanced LED based Light Extinction Automatic Optical Monitor Technology to accurately measure and interpret the ISO/NAS cleanliness code level in real-time. Maintaining oil cleanliness within the specified ISO/NAS cleanliness code level is essential for ensuring smooth system operation and preventing component wear and damage.

By continuously monitoring the cleanliness of the oi and adhering to recommended levels, the operators can minimize the risk of costly downtime, extend equipment lifespan by enabling proactive maintenance strategies to be implemented, such as filtration and oil replacement, before contamination reaches critical levels.

Product specification, depending on the selected type

- Maximum operating pressure: 420 bar

- Measurement flow rate: 20 ... 400 ml/min

- Viscosity range: 1 ... 1000 mm²/s

- Media temperature range : -25 ..... +80°C

- Measures and Display format : ISO 4406, NAS 1638, AS 4059E.

- Communication options – RS485, MOBUS, CANBUS, 4…20 mA.

- Memory Data storage possible

- Relay function available in specific variants

- Compact design

- Light weight ~ 1.5 kgs

Contact us today to learn more about our Oil Particle Counter and discover how it can revolutionize your maintenance practices. Stay ahead of the curve, protect your investments, and optimize performance with precision maintenance solutions tailored to your needs

Automatic Laser Particle Counter for Hydraulic Systems

In modern fluid management, precision is paramount. Our Automatic Laser Particle Counter is engineered to deliver accurate, real-time contamination monitoring in hydraulic and lubrication systems. With advanced optics and detection technology, it identifies and measures solid particle contamination across multiple size ranges.

Fully compliant with ISO 4406, SAE 4059, and NAS 1638 standards, this device provides comprehensive insights into fluid cleanliness, helping you prevent equipment failures, reduce downtime, and extend component life.

Key Specifications of Laser Particle Counters

- Measurement formats: ISO 4406, NAS 1638, AS 4059E

- Range: up to NAS 15 / ISO 25/23/21 / SAE 15

- Maximum operating pressure: 420 bar

- Measurement flow rate: 50 – 800 ml/min

- Memory capacity: 3,000 – 4,000 readings

- Viscosity range: 1 – 400 mm²/s

- Media temperature: -25°C to +80°C

- Integrated graphics-capable printer

- Data output: on-screen or PC connection

- Communication: RS232, RS485

- Robust, industrial-grade design

- Unit weight: ~10 to 15 kg

Benefits of Using Automatic Laser Particle Counters

- Ensures compliance with international cleanliness codes

- Provides real-time contamination data

- Enables proactive maintenance to reduce downtime

- Safeguards hydraulic & lubrication system components

- Compact and robust design for industrial use

Partner with us to safeguard your systems with advanced contamination monitoring technology. Our Automatic Laser Particle Counter ensures precise fluid cleanliness analysis, unlocking new levels of system performance and reliability.

Aqua Sensor for Hydraulic Oil & Lubrication Systems

In hydraulic and lubrication systems, even small amounts of water can cause oil acidification, corrosion, and performance loss. Early detection and removal are crucial to avoid system failures, downtime, and costly repairs. Our Aqua Sensor provides a reliable way to monitor and manage water contamination in oil, ensuring smooth operation and longer equipment life.

How Aqua Sensors Measure Water in Oil

The two common methods are:

- PPM (Parts Per Million) – widely used but limited as it doesn’t account for oil temperature changes.

- Saturation Level (%) – adjusts for temperature variations, providing a more accurate and reliable reading.

Our advanced Aqua Sensor measures dissolved water content online, in real time, as a saturation percentage. It works independently of oil type, age, and temperature:

- 0% = water-free oil

- 100% = fully saturated oil

Benefits of Using Aqua Sensors

- Continuous real-time monitoring of water contamination

- Prevents oil acidification and corrosion of system components

- Ensures longer oil life and reduced maintenance costs

- Independent of oil type, age, or temperature

- Improves system reliability and reduces downtime

With our Aqua Sensor, you can effectively monitor and control water content in oil, ensuring maximum system reliability, lower costs, and extended equipment lifespan.

FAQ

Techknow Engineering's Oil Filtration & Contamination Sensors ensure optimal hydraulic and lubrication system performance by detecting and removing impurities, contaminants, and particles in oil.

These sensors continuously monitor oil condition by measuring particle counts, water content, and contamination levels. Filtration systems then remove impurities to maintain optimal oil quality and protect equipment.

Our solutions reduce premature wear, minimize downtime, and extend the life of hydraulic systems and machinery by keeping oil clean and alerting operators early to contamination problems.

These systems can be installed in hydraulic reservoirs, gearboxes, compressors, turbines, lubrication circuits, or any machinery where oil cleanliness is critical for smooth operation.

- High-efficiency filtration systems

- Real-time contamination and particle monitoring

- Water detection capability

- Durable housings built to industry standards

- Visual/electronic alert systems for early warnings

Service intervals depend on application and contamination levels. Filters should be replaced when sensors indicate high particle counts or as per manufacturer guidelines to maintain cleanliness.

Yes. Certain models allow replacement of filter elements while retaining the sensor assembly, offering cost-effective and sustainable operation.

Industries that rely on clean oil for efficient operations include:

- Construction & Heavy Machinery

- Oil & Gas Operations

- Marine & Offshore Equipment

- Power Generation

- Mining & Earthmoving Equipment

- Industrial Manufacturing

- Automotive & Transportation Fleets

- Agriculture

We provide premium Oil Filtration & Contamination Sensors from trusted manufacturers including Hydac, Bosch Rexroth, HENGST, FILTREC, MP Filtri, and Donaldson, ensuring accurate monitoring, efficient filtration, and long-term protection for hydraulic systems.