High-Performance Hydraulic Cylinders for Industrial and Mobile Applications

Reliable Hydraulic Cylinder Manufacturing & Supply

Hydraulic cylinders are essential wherever precise linear force is needed from light-duty machinery to heavy industrial systems. These units can generate pressure ranging from a few bars to several tonnes per square inch.

Being a core component of any hydraulic system, the accuracy and quality of a cylinder directly affect the machine’s performance and durability. That’s why we focus on precision manufacturing and robust quality assurance.

Why Choose Our Hydraulic Cylinders

The precision of hydraulic cylinder manufacturing ensures reliable and safe operation. Our expert team uses advanced techniques, superior materials, and tight tolerances to guarantee performance and longevity in every unit.

Each hydraulic cylinder is engineered for optimized weight, energy efficiency, long service life, and easy maintenance - delivering cost-effective performance you can trust.

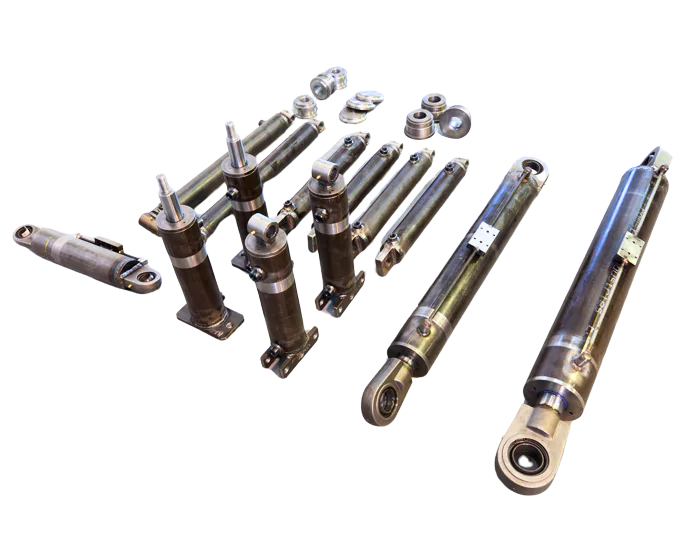

Types of Hydraulic Cylinders We Offer

- Mill Type Hydraulic Cylinders

- Tie Rod Hydraulic Cylinders

- Welded Hydraulic Cylinders

- Telescopic Hydraulic Cylinders

- Servo Hydraulic Cylinders

Hydraulic Cylinder Parts & Services

Custom Manufacturing, Repairs & Seal Kits

- Seal kits, guide rings, piston assemblies, and rod re-chroming

- Custom bore sizes and stroke lengths up to 7,500 mm

- Operating pressures up to 500 bar

- Material options: Carbon Steel and Stainless Steel

- Feedback unit and special mounting options available

- Hydraulic cylinder repair and replacement services

A hydraulic cylinder includes a piston and rod assembly that converts hydraulic pressure into controlled linear motion. Our design ensures maximum strength, performance, and safety.

Key Design Details Required

- Working type: Single acting or Double acting

- Number of stages and stroke length

- Bore and piston rod diameter

- Operating pressure and temperature range

- Port size and mounting configuration

- Construction: Welded / Bolted / Custom

For existing cylinders, provide retracted length, stroke, barrel O.D., and mounting details for an accurate replacement or rebuild.

Types of Seals Used

Static seals (O-rings, backup rings) and dynamic seals (piston, rod, and wiper seals) ensure fluid containment and prevent leaks under high pressure. Guide rings help maintain alignment and prevent metal-to-metal contact.

O-rings and gaskets for stationary joints to prevent leakage.

Rod and piston seals that handle motion and maintain pressure integrity.

Prevent friction and metal contact between the piston and cylinder bore.

We provide premium-quality hydraulic cylinder seal kits compatible with major brands, ensuring optimal sealing performance and durability.

FAQ

We provide high-quality Hydraulic Cylinders from trusted manufacturers including Hydac, Rexroth, Eaton-Vickers, Yuken and our own customised Techknow Engineering Enterprise make, ensuring reliable performance, durability, and long service life for industrial hydraulic applications.

Hydraulic cylinders convert hydraulic fluid pressure into linear motion and force, powering equipment such as presses, cranes, mobile machines, and industrial automation systems.

We offer Mill Type, Tie Rod, Welded, Telescopic, and Servo Cylinders, along with replacement parts and complete repair solutions.

Yes. We design cylinders to your specifications, including bore size, stroke length, pressure, temperature range, and mounting preferences.

Our cylinders handle pressures up to 500 bar, diameters up to 750 mm, and lengths up to 7,500 mm, using carbon steel or stainless steel with multiple seal options.

Choices include Rod Clevis, Rod Eye, Spherical Rod Eye, Cross Tube, and Trunnion, as well as square or round flange configurations.

Yes. We supply complete static and dynamic seal kits — including guide rings — for maintaining or overhauling cylinders of any brand.

Absolutely. We offer professional repair services and can source or manufacture direct replacements for obsolete or damaged cylinders.

They deliver high precision, energy efficiency, long service life, and easy maintenance for safe, reliable operation in demanding conditions.